At ECEMI, die manufacturing plays a central role in our aluminum extrusion process. With our advanced in-house die shop, we design and produce high-precision extrusion dies that meet strict standards of accuracy, durability, and consistency.

What We Do

🧠 Custom Die Engineering

We develop dies tailored to each client’s profile, ensuring maximum extrusion efficiency and minimal material waste.

📐 CAD/CAM Design

Our engineering team uses advanced design software to produce detailed 3D models and simulations of the die performance.

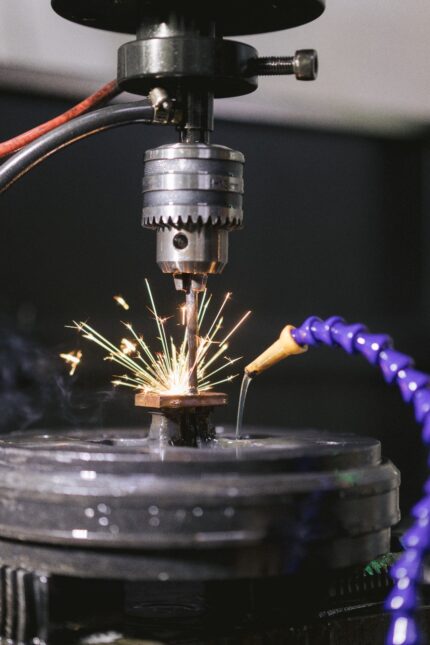

🖥️ Precision CNC & EDM Machining

With high-tech machinery, we achieve accurate shapes, smooth finishes, and tight tolerances on every die.

🔄 Prototype & Testing

We simulate and test die designs before production to ensure flawless functionality and durability.

🧪 Material Selection Expertise

We choose high-grade steel alloys for optimal die strength, wear resistance, and longevity.

Our Process

🔧 Die Design & Simulation

We use advanced software to model each die with high accuracy and simulate its performance before production.

⚙️ High-Precision Machining

CNC and EDM machining are used to achieve exact dimensions and smooth surface finishes.

🔥 Heat Treatment

Improves hardness and wear resistance for longer die life.

🛠️ Die Maintenance & Correction

Regular inspection, polishing, and correction ensures consistent performance.

Why In-House Die Manufacturing Matters

⚡ Faster Turnaround

By controlling the die-making process in-house, we significantly reduce lead times and project delays.

🎯 Tighter Quality Control

Every step is managed by our team — from design to testing — ensuring consistent, high-quality results.

🔄 Rapid Modifications

Need to tweak a design? Our in-house team can quickly adapt dies to new specs without external delays.

💰 Cost Efficiency

Minimizing third-party involvement cuts unnecessary costs and improves overall project ROI.

🤝 Improved Collaboration

Seamless communication between engineering, production, and clients leads to better product outcomes.

Preparing for Future Growth

🚀 Capacity Expansion

We’re investing in more CNC and EDM machines to meet growing demand and support high-volume projects.

🔬 Advanced Technologies

From AI-assisted die design to real-time process monitoring, we are integrating smart tools to push boundaries.

👨🏭 Skilled Workforce Development

We’re continuously training our engineers and technicians to stay ahead in precision manufacturing.

🌍 Sustainable Practices

Future upgrades include energy-efficient systems and recyclable die materials to support greener production.

🧩 Modular Die Systems

We’re exploring modular die technologies to enable faster changeovers and multi-profile extrusion in one run.

Industries We Serve

🏗️ Architecture

🚧 Construction

🚚 Transportation

⚙️ Industrial Systems

🧩 Custom Fabrication